Cruise ships use power equivalent to approximately 50,000 horsepower, with one horsepower equal to 746 watts. A ship engine is designed to directly drive huge propellers, or produce electricity that is diverted to drive the propellers. A cruise ship can travel at remarkably fast speeds of around 30 miles per hour without undue stress on the engine; a remarkable feat or marine engineering.

In 2003, Carnival Cruise choose common-rail, four-stroke engines developed by MAN Diesel & Turbo. These engines were designed to operate in 133,000 tonne cruise ships and are capable of delivering 83,700 horsepowers (62,400 kW).

Cruise ship engine types

The cruise industry has been around since the mid 1800s, when ships were propelled by steam engines. Modern cruise ships run on diesel engines, or more recently gas turbines introduced by Royal Caribbean as a greener alternative. Diesel powered vessels are fitted with catalytic-reduction equipment and systems to treat exhaust and minimise environmental impacts. Advantages of a gas turbine system include the need for fewer maintenance staff and a simpler spare parts inventory. A steam turbine is synchronised with the gas engine, recovering heat which is then transformed into electricity to power water heating, air conditioning and other onboard services.

Regardless of the engine type, a lot of fuel is required. A cruise ship carries enough fuel to travel non-stop for up to two weeks, and itinerary stopovers are factored in with refuelling an essential consideration. The cost of running a cruise ship is partially determined by fluctuations in global fuel prices.

Cruise ship propellers

Propellers, commonly called screws, are an integral component of any cruise ship, and are used to provide both forward and reverse momentum. These huge propellers rely on torque, or power rather than speed, to provide the motion required to propel a huge vessel often weighing over 200,000 tons. Cutting-edge technology has seen the recent introduction of azimuth thrusters enabling 360 degree swivel of the propellers for incredible manoeuvrability. They also facilitate greater fuel efficiency and decreased stopping distance, and are equally suitable to both diesel electric and gas turbine engines.

Green innovations in cruise ship design

Energy savings are an important feature of modern cruise ship design, especially with savvy travellers expecting environmentally conscious design solutions. New ships are often built using a silicone hull coating that enhances performance and lowers fuel usage. The introduction of LED light bulbs and automated lighting control systems are another cost saving innovation, especially considering large cruise ships host more than 5,000 passengers.

Other ongoing improvements include energy-efficient air-conditioning, heating and ventilation, using inverters for optimum performance. Information analytics via monitoring systems play an increasingly important role in keeping running costs at the desired level.

Stability, strength and trim

Technology software controls are used to monitor performance of the ship, especially related to fuel consumption, and categorised as stability, strength and trim. Stability refers to the way a ship handles both still water and waves. Strength is created using the best shipbuilding materials as opposed to the heaviest materials. A heavy ship, although tough, will also be slower, have worse fuel efficiency and will cost more to build. Trim refers to the overall balance of the ship. A cruise ship that accommodates maximised fuel efficiency coupled with advanced energy saving and recycling measures is the targeted expectation of progressive cruise lines.

Large cruise vessels were previously exposed as environmentally unfriendly behemoths polluting our oceans, but advances in design and energy efficiency have welcomed a new breed of ocean liner created to exceed government regulations and provide passengers with the assurance that their vacation is good for the environment as well as their wallet.

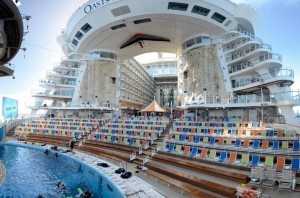

featured image by jgmorard